NMR

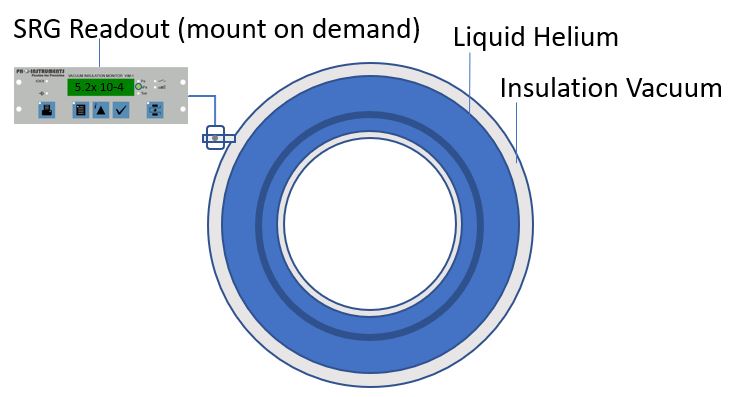

Nuclear Magnetic Resonance uses vacuum insulated superconducting magnets at liquid Helium temperature. The SRG Technology can measure the insulation vacuum quality and its change over time, especially during manufacturing and in case of service (magnet at ambient temperature).

Grids / Cables

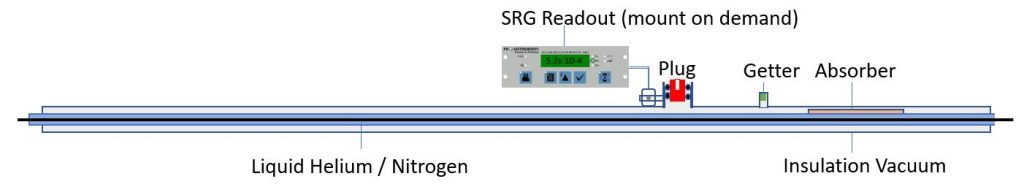

Superconducting cables are used for loss free electrical energy transport. Besides the efficiency gain, the power density is increased significantly, meaning the same power can be transferred through a small diameter cable ( cm² ) while conventional lines would have to use multiple wires over long distances (m²), especially in cities where it may be the only suitable method. Superconducting cables work at liquid Helium or liquid Nitrogen temperature, vacuum insulated. The vacuum insulated electrical power lines are “per definition long”, theses tubes have a very bad aspect ratio for the generation and measurement of vacuum. The SRG Technology should be able to measure the insulation vacuum quality at different points of the cable during manufacturing, in case of service and, in principle, products can be developed that measure continuously. Applications during operations need to be discussed with our applications specialists.

The page Cryo Technology contains a picture of our SRG VIM-1 in action at a vacuum insulated or vacuum jacketed pipe.

| Features | Benefits |

No need to open the sealed vacuum chamber | Ideal for monitoring sealed vacuum systems |

No electrical feedthroughs | Chamber remains sealed |

| Electromagnetic/Mechanical measurement | Does not affect pressure or gas composition Insensitive to vacuum process and temperature conditions |

All-metal Sensor (in metal or glass tube) | Contactless measurement provides long-term stabilityHigh accuracy direct vacuum measurement No component to fail or replace Cost effective Sensor concept Glass sensor tube maybe removed and be disposed of before shipment |

Removeable Sensor head/readout | Electronics remain protected |

High intrinsic accuracy/reproducibility | No adjustments: Sufficient accuracy for most applications |

No electronics remain after measurement | Corrosion and “outdoor” weather resistant |

One-button operation | No special training or specialist needed |

Protection cap and magnet for storage | No breakage risk or damage of the ball´s surface |

Remote PC control | User friendly |

| Serviceable sensor | Quick and easy to clean and reassemble |

| Single connection to multiple units via RS-485 interface | Simultaneously monitors multiple vacuum chambers |