Introduction

The SRG Transducer is a process manometer based on Spinning Rotor Gauge technology. Compared to other methods (hot or cold cathodes, capacitive pressure sensors), Spinning Rotor Gauges are highly accurate, long-term stable and do not influence the pressure signal that is measured in any way (no temperature input / ionization / gettering / drifts etc.). The simple geometry and a stainless steel rotating ball that moves smoothly via electromagnetic forces is ideal for high-purity processes with various gases.

Spinning Rotor Gauges (SRGs) were previously considered complex to operate and were therefore used almost exclusively in calibration laboratories. A main application was the calibration of high vacuum measuring devices, e.g. of ionization measuring methods (4 x 10-4 Torr to 4 x 10 -7 Torr / 5 x 10-4 mbar to 5 x 10-7 mbar).

Advantages – Autonomous, high-accuracy measurement, long-term stability

DosiTorr is a new type of SRG transducer based on proven and tested components. It works completely autonomously and for the first time offers the advantage of integrating this technology directly into a system. Due to its function, DosiTorr meets the highest purity requirements and works without influencing the medium to be measured. It is a direct, mathematical / physical process that only uses the effect of decelerating a rotating ball as a means to measure the pressure in the vacuum chamber.

Since only electromagnetic forces interact with the rotating ball, SRGs operate wear-free, at room temperature, have extremely long-term stability, and do not generate any ions, plasmas, heat (thermo couples/piranis), particles, etc. that may interfere with the process.

There are no mechanically stressed components that can be deformed, such as Inconel or ceramic membranes.

For the first time, there is a battery function for high-accuracy applications, which ensures that the rotating ball is seated in a controlled manner in every operating state to protect integrity of the gauge.

A reliable measurement is provided due to an improved readout head design. The DosiTorr generates a magnetic field that is twice as strong (90 mT) as previously available with Spinning Rotor Gauges. The standard rotation frequency of 615 Hz of the sphere results in a significantly more stable suspension in the magnetic field. Both effects result in a higher tolerance to vibrations and an often-imperfect alignment of the sensor tube.

The measuring head is magnetically shielded, typically does not influence the process, and is not influenced by external magnetic fields.

Measurement principle

The Spinning Rotor Gauge is based on the effect that gas molecules slow down a moving body as they are adsorbed on its surface. The statistically distributed molecules striking from all directions are accelerated accordingly and slow down the body (momentum transfer, area-related particle flux density).

The desorption of the accelerated gas molecules does not contribute to the movement of the body, as this takes place in an undirected manner and the additional energy absorbed by the molecules is released to the walls of the vessel (molecular range approx. < 4 x 10-4 Torr / 5 x 10-4 mbar) or is released to other molecules (> 4 x 10-4 Torr / 5 x 10-4 mbar). At pressure in the so-called transition area, the gas viscosity is automatically compensated by means of an integrated temperature measurement.

In the case of the Spinning Rotor Gauge, a simple precision ball is used as the body and the deceleration is determined by the decrease in the rotational frequency. Factors such as the molecular mass and temperature changes are only included in the measurement in an easily determinable root ratio, coatings only with the minimal increase in the spherical radius.

Additionally, within small limits, variable factors determine the braking of the rotating ball:

- The “residual drag” is pre-determined at the factory and without any further setting, an error of typically ± 2 x 10-6 Torr/mbar remains. With a fine zero-point adjustment (automated) this goes to 0. This factor is a spherical material property.

- The “molecular drag” is the actual deceleration by the surrounding medium and proportional to the pressure. The molecular drag contains the accommodation coefficient / calibration factor and varies with an ideally smooth sphere (factor 1) by maximum ± 6 %. This effect results from the roughness of the spherical surface. With balls pre-calibrated (standard) at the factory, an accuracy of ± 1 % of the measured value can be achieved.

It should be noted that even without setting the calibration factor or the zero-point, and even after operating for years, the system still has a high intrinsic accuracy in high vacuum, which cannot be achieved by any other vacuum measurement method and is more than sufficient for many applications.

Measurement Range

Due to their operating principle, Spinning Rotor Gauges can be used in pressure ranges from atmosphere to UHV. Due to geometric and electromechanical conditions, however, they are optimized for the pressure range, in which they achieve uniquely high levels of accuracy and long-term stability:

1 % accuracy of reading between 0.1 Torr and 7 x 10-7 Torr /

0.1 mbar and 1 x 10-6 mbar

<1 % drift per year

Measuring range in general: 7 Torr to 4 x 10-7 Torr / 10 mbar to 5 x 10-7 mbar

| Measurement Principle | Spinning Rotor Gauge |

| Measurement range | 7 Torr to 4 x 10-7 Torr 10 mbar to 5 x 10-7 mbar |

| Accuracy | 7 Torr to 0.07 Torr 10 mbar to 0.1 mbar approx. 10 % of reading 0,07 Torr to 7 x 10-7 Torr 0,01 mbar to 1 x 10-6 mbar 1 % of reading |

| Long term stability | < 1 % drift per year |

| Wetted Material tube/ball | Stainless Steel |

| Alignment | Horizontal |

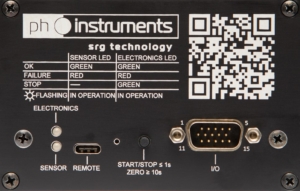

| Analog Interfaces | USB Type C, Bluetooth, High Density 15-polig |

| Digital Interfaces | USB, Bluetooth, RS 232, RS 485 |

| Reaction Time (fast mode) | 1 s |