ION Check - SRG Technology based Ion Gauge calibration and comparison system

The Ion Check is a complete solution to calibrate and compare high vacuum gauges. A spinning rotor gauge is used as a certified, accurate and long-term stable pressure standard. The ION Check is compact and optimized for this application, consists of an oil free and vibration insulated high vacuum system, a gas dosing unit for this pressure regime and a hard- and software to read out and calibrate vacuum gauges with analog output.

In many processes especially the range from 1 x 10-4 mbar/ Torr to 1 x 10‑6 mbar/Torr is of interest, hard to keep stable and get reliable pressure sensor signals (e.g. due to missing calibration and usage). Most methods of pressure measurement in mentioned range are based on an indirect measurement of the ion current (hot cathodes (HC) / Bayard-Alpert or cold cathodes (CC) / Penning). Due to their function, these methods require high energy densities to generate ions. High energy densities at filaments / plasmas influence the vacuum to be measured (sputtering / gettering / outgassing) and ultimately stability of the process itself. Coatings and aging / corrosion have an influence on the ionization rate and its detection. This simulates a non-existent change in pressure (drift). This drift is further accelerated by contact with process gases. These unspecified inaccuracies are difficult to identify. The consequences can often only be recognized through inadequate process results. Thus, reliable, reproducible, and long-term stable measurement with specification of accuracy is hardly possible.

The Spinning Rotor Gauge (SRG) is a recognized, highly accurate and long-term stable transfer standard and therefore represents a unique option for characterizing and checking ionization gauges:

- “in-situ”, directly on the process, using an SRG transducer (DosiTorr)

- “ex-situ”, outside of the process using the ION Check System.

The SRG system allows simple, accurate setting and determination of pressures between 5 x 10-7 and 1 x 10-2 mbar with high-purity calibration gases.

In order to directly display differences within the measuring process to be checked, e.g. two ionization gauges can be included in the comparison. Ultimately, the direct comparison on the IONCheck also enables a reliable selection of devices before they are used (possibly in comparison to an in-house “golden” or verified standard).

Advantages of SRG Measurement

Compared to other high vacuum measurement methods, the integrated Spinning Rotor Gauge is highly accurate, has long-term stability and does not influence the vacuum to be measured (no temperature input / ionization / gettering / sputtering / bending of membranes, etc.). The measuring method is based on a stainless steel ball that is suspended by electromagnetic forces and set in rotation. The pressure is only determined by the inductively measured decrease in spherical rotation frequency (caused by the adsorption / desorption of the gas particles on the spherical surface). The SRG measurement system is wear-free, linear and mathematically precise.

In general, Spinning Rotor Gauges were previously considered complex to use and were therefore almost exclusively used in calibration laboratories with highly trained staff. The Spinning Rotor Gauges from ph-instruments GmbH are characterized by their ease of use.

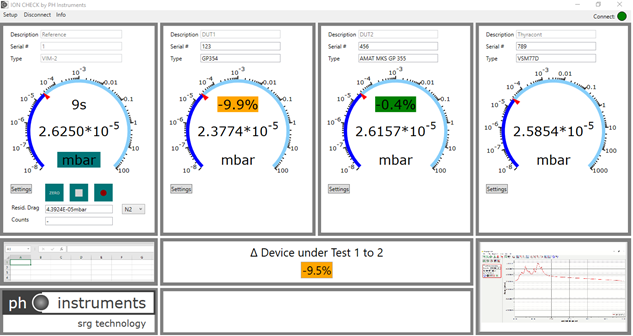

Software adapted to the application is used to synchronously save the measured values from as many as four measuring sensors (two of those are Devices under Test DUTs) on the IONCheck.

Operating and Calibration Software

The ION Check is equipped with optimized software for operating the SRG, including the test items. The software interface is operated using a touch display, avoiding cables and external input aids such as keyboard and mouse (which can be connected as an option). The saved data is output via a USB connection. The Windows 10-based computer can also be integrated into a network via a LAN socket. The output is visualized in an overview by means of four analog pointer instrument modeled displays, as shown in the figure above. In detail, the measured values can be read or stored precisely in exponential notation. In addition, the percentage deviation of the test items from one another and from the reference, the SRG, is shown.

The four pressure measurement values are saved in parallel in a CSV file. Further processing of the data can thus take place in commonly used spreadsheet or visualization programs.

The software and underlying hardware of the ION Check can characterize two vacuum pressure gauges with widespread analog output (0 – 10 VDC) and 24 VDC power supply. The analog inputs of the ION Check can be parameterized. The electrical connection is made using special cables supplied by ph-instruments GmbH and should be requested at time of ordering. Do not substitute nonstandard connecting cables on your own. The hardware can be destroyed (the warranty is void).

| ION Check Specifications | |

| Measurement Principle | Spinning Rotor Gauge (+ Pirani/ Penning) |

| Adjustable pressure range | 5 x 10-7 mbar to 1 x 10-2 mbar (max. 1 mbar) 4 x 10-7 Torr to 7 x 10-3 Torr (max. 1 Torr) |

| Accuracy SRG | 0.1 mbar to 1 x 10-6 mbar 1% of reading 0.07 Torr to 7 x 10-7 Torr 1% of reading |

| Measurement time SRG | 3, 5, 10, 20, 30 s |

| Evaluation cycle of the system | < 1 s |

| Long-term stability | < 1% Drift per year |

| Number DUT | 2 parallel |

| Vacuum connection DuT | KF25 (others via adapter) |

| HV pumping system | Pfeiffer PM 015 887 AT / diaphragm vacuum backing pump |

| Bypass pump | diaphragm vacuum backing pump |

| Digital interfaces | USB-C, Bluetooth (opt), RS-485, LAN |

| PC operation / GUI | Win10, ION Check App |

| LCD Touch Display / Mini PC | ASUS VT168H / Intel® Celeron® N3450 processor: 8GB DDR4, 128GB M.2 SATA SSD |

| Plug compatible (cable included) | MKS/GP 354, MKS /GP 355, MKS 971B |

| Plug compatible general | CC/HC/Pirani with 24 VDC power supply and 0-10 VDC analog output (cable on request) |

| Operating Temperature | 10 bis 40 °C (50 to 104 F) |

| Power Consumption | 230 VAC, 50 Hz, < 2 A uninterruptible power |

| Calibration gas (optional) | N2 (further on request) |

| Weight | 90.8 kg (216 lb) |

| Dimensions | L x B x H = 610 x 610 x 1200 mm (24 x 24 x 47-1/4 inches) |