Vacuum insulated glazing / VIG is a great opportunity to improve building insulation and safe energy for heating and cooling. In the VIG application the pressure working area is in the range between 10–2 mbar (bad VIG), 10-3 mbar (good insulating VIG) and 10-4 mbar (perfect VIG), where the SRG is an ideal, completeley sealed instrument for pressure monitoring (outgassing- & permeatioin- tests etc.). More information about vacuum, the best choice for insulation can be found @ Vacuum Insulation.

For gas filled triple glazing, that are the current standard, heat conductivity of 0.7 W/(m2K) is close to the limit. Further improvements can be achieved when using vacuum insulated window panels. A U-value of 0.3 W/(m2K) or even better is possible. The super slim design is another advantage of VIG.

VIG is in China, Japan, USA and Taiwan already quite common. However policies in Europe and North America, requiring a U-value (parameter for heat conductivity) of 0.7 W/(m2K) or better, boost the interest in vacuum glazing technology and manufacturing capabilities.

The key knowledge of VIG is to create leak proof panels, that keep the vacuum quality stable over decades.

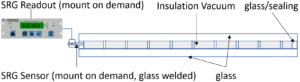

SRGs can be used during the development of panels for outgassing and permeation testing (to monitor minimal drifts of the insulation vacuum). Simple sensors can be melted, welded or brazed to panels with non magnetic metal tubes or glass tubes. Spinning Rotor Gauges, as a passive vacuum sensing method, are the best option to monitor the vacuum of interest to detect any minimal change in pressure. In the end the sensors can be reused. That could also be useful for VIP / Vacuum insulated panels.

Furthermore manufactured panels with attached sensors provide the opportunity of an early quality check or quality control for documentation. Glass tubes with sensors inside that were melted to the panel before, can be removed from a VIG with minimum effort.

Vacuum insulated Glazing / VIG

Research on vacuum building insulation requires a suitable, trust worth method to enable real improvements. SRG pressure measurements between 10 and 10-6 mbar or Torr are super reliable and reproducible.

| Features | Benefits |

| No need to open the sealed vacuum panel | Ideal for monitoring sealed vacuum systems Easy to connect to port |

| No electrical feedthroughs | Chamber remains sealed |

| Electromagnetic/Mechanical measurement | Does not affect pressure or gas composition Insensitive to vacuum process and temperature conditions |

| All-metal Sensor (in metal or glass tube) | Contactless measurement provides long-term stability High accuracy direct vacuum measurement No component to fail or replace Cost effective Sensor concept Glass sensor tube maybe removed and be disposed of before shipment |

| Removeable Sensor head/readout | Electronics remain protected Measurement and mounting on demand One head for multiple sensors Heads are universal, fit all sensors |

| High intrinsic accuracy/reproducibility | No adjustments: Sufficient accuracy for most applications Long term stability for years |

| No electronics remain after measurement | Corrosion and “outdoor” weather resistant |

| One-button operation | No special training or specialist needed |

| Protection cap and magnet for storage | No breakage risk or damage of the ball's surface |

| Remote PC control | User friendly |

| Serviceable sensor | Quick and easy to clean and reassemble |

| Single connection to multiple units via RS-485 interface | Simultaneously monitors multiple vacuum chambers |