Cryo Technology is widely used in generation, controlling and keeping environments/systems at low temperatures. A lot of electrical, mechanical energy is needed to get a system cooled down, to pump heat out of the system, either directly by closed cycle processes or indirectly using evaporation enthalpy of liquified gases. The whole cool down process is always contradicted by the natural heat transfer from warm to cold areas. A proper insulation is a must to minimize the energy amount needed to work against the natural heat transfer.

Vacuum insulation is the best option to avoid heat transfer. Our Spinning Rotor Vacuum Gauges are the ideal device to control vacuum insulation without breaking the vacuum.

Applications can be either for long term storage of gases and organic probes, chemical processing or to get into temperature regimes where special materials get superconducting.

Liquid Gases can be used for cooling, but could be themselves the matter of interest because of effective storage and transportation possibilities (relatively high volume and storage density compared to pressurized gases).

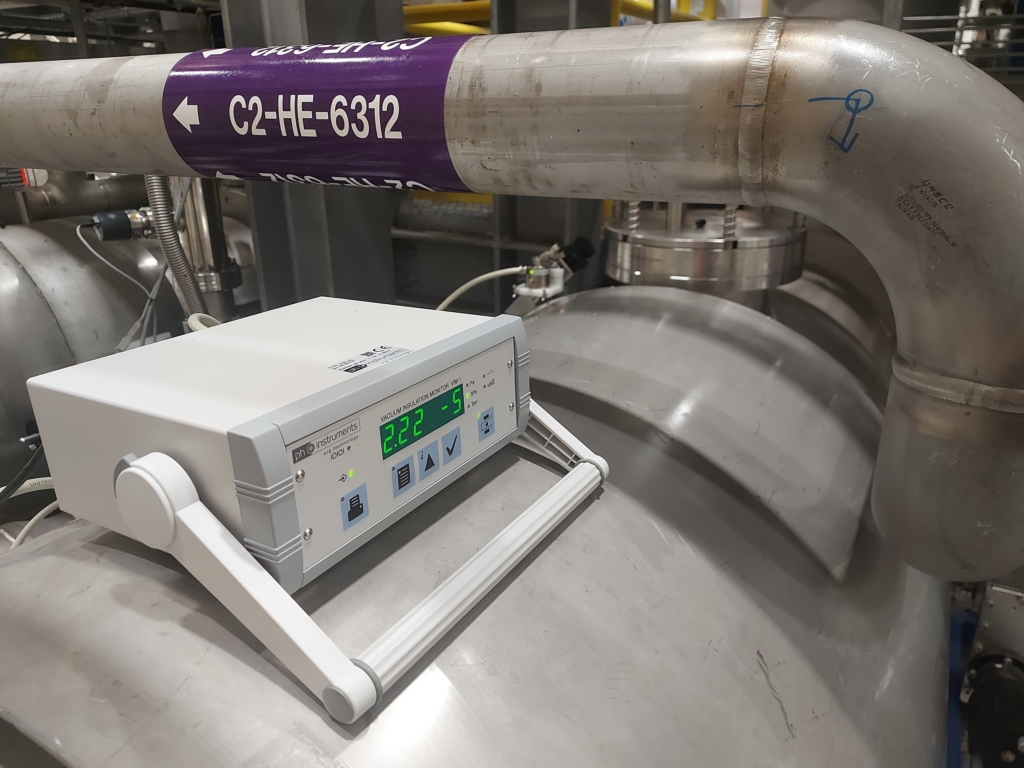

The picrure on the left shows, a VIM that is used for monitoring the a vacuum jacketed Helium transfer pipe.

| Features | Benefits |

| Separation of the inexpensive sensor from the costly electronics” | No need to open the sealed vacuum chamber Ideal for monitoring sealed vacuum systems Easy to connect to port |

| No electrical feedthroughs | Chamber remains stably sealed even after thermal stress |

| Electromagnetic/Mechanical measurement | Does not affect pressure or gas composition Insensitive to vacuum process and temperature conditions |

| Metal sensorsphere (in a metal or glass tube) | Contactless measurement provides long-term stability High accuracy and precision direct vacuum measurement No component to fail or replace Cost effective Sensor concept Glass sensor tube maybe removed and be disposed of before shipment Very clean and sterile concept Weldable sensor solution |

| Removeable Sensor head/readout | Electronics remain protected Measurement and mounting on demand One head for multiple sensors Heads are universal, fit all sensors |

| High intrinsic accuracy/reproducibility | No adjustments: Sufficient intrinsic accuracy for most applications Long term stability for years |

| No electronics remain after measurement | Corrosion, radiation (UV, ...) and temperature resistant |

| One-button operation | No special training or specialist needed |

| Protection cap and magnet for storage | No breakage risk or damage of the ball´s surface |

| Remote PC control | User friendly |

| Serviceable sensor | Quick and easy to clean and reassemble |

| Single connection to multiple units via RS-485 interface | Simultaneously monitors multiple vacuum chambers |